By Source:

Classification

of defects: The listing

of possible defects of a unit, classified according to their seriousness. Note:

Commonly used classifications: class A, class B, class C, class D; or critical,

major, minor and incidental; or critical, major and minor. Definitions of these

classifications require careful preparation and tailoring to the product(s)

being sampled to ensure accurate assignment of a defect to the proper

classification. A separate acceptance sampling plan is generally applied to

each class of defects.

Commonly TIC industry adopted 3 types of defect classifications which included Critical, Major, Minor defect.

Critical Defect = Not Allowed

Defects that could result in hazardous or unsafe conditions for individuals using or maintaining the product, as well as defects that contravene legal regulations.

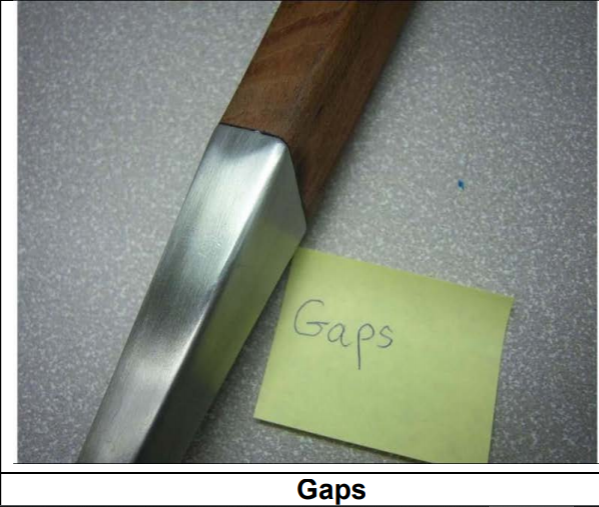

Major Defect

Functional defects reducing the usability or strength of the product as well as obvious visual defects that would reduce the sales value.

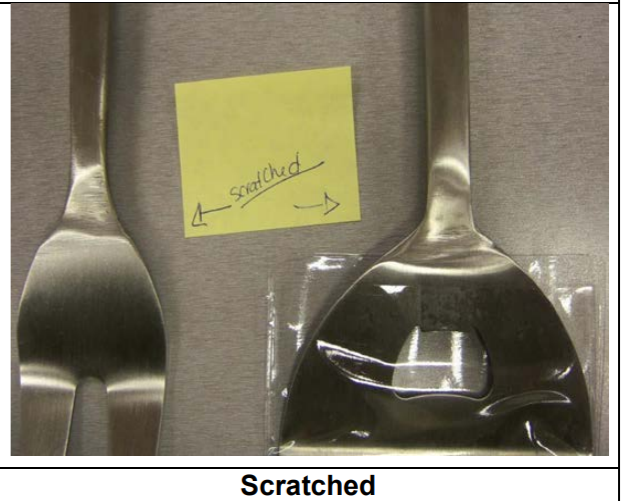

Minor Defect

Defects that will not reduce the use of the product, but may influence the sale.

General guideline for determining major or minor defects at arm’s length

Any idea of defect classification,please feel free to contact us :info@veriquality.net